Pebble-Heater Technology

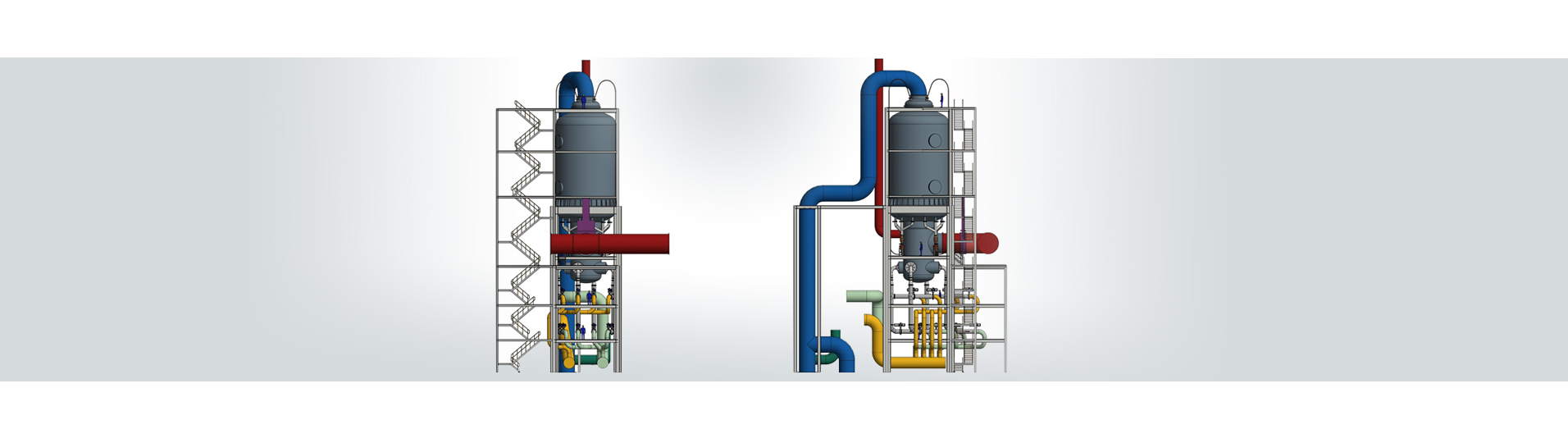

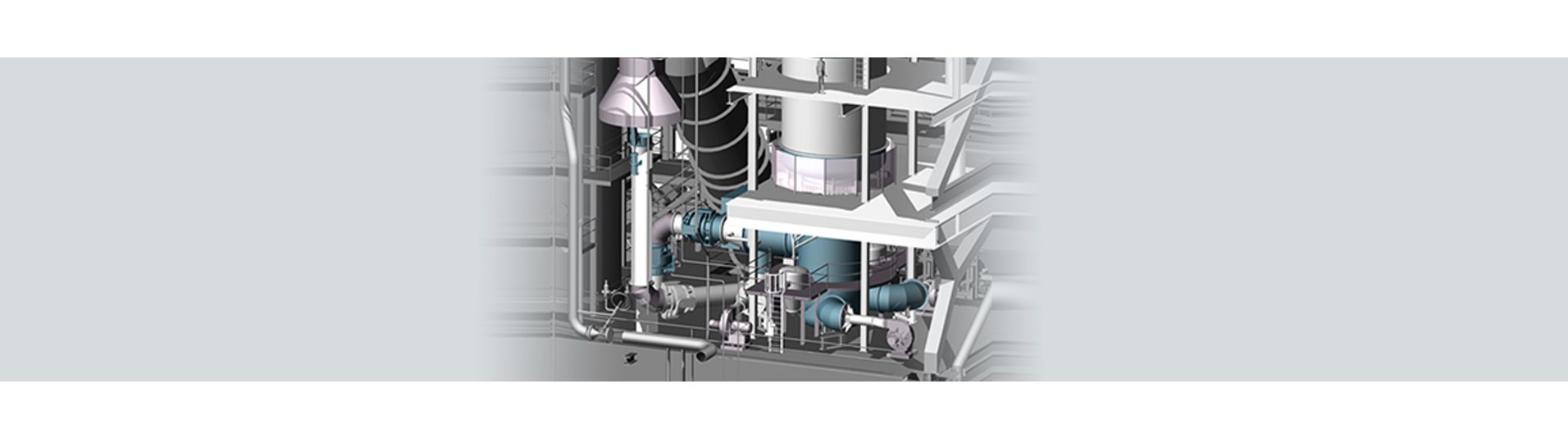

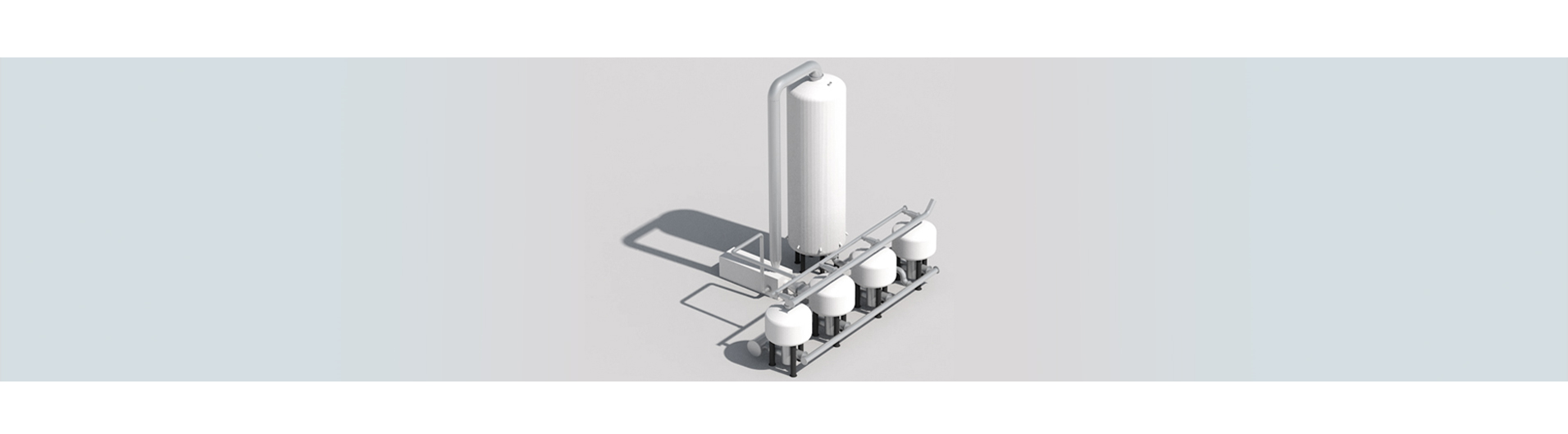

The new regenerative heat exchanger is referred to as "Pebble-Heater" - a name already known in technical practice. It is filled with bulk material consisting of spherical pebbles and may operate at high temperatures to heat and cool gaseous media. The differences towards the state-of-the-art start with the flow direction: the fluid flows radially through the pebble-bed which is fixed between two concentric, permeable cylinders, referred to as hot and cold grid.

All other extraordinary characteristics result from that difference which only at first sight appears small. Higher flow velocity and/or smaller pebble diameters may be used, as there is no danger of fluidization. That provides a very high specific surface (or surface to volume ratio) and consequently an excellent heat transfer. A thermal efficiency of 95 % has easily been achieved (without any additional off-gas recuperation for preheating combustion air or gas). A unit with a recuperation rate of over 98 % is already in operation. In addition, those results are achieved at small exergy losses, i.e. with low temperature difference (as little as 20 K) between heating and heated gas - and all that at temperatures of up to 1,500°C.

- PEBBLE-HEATER - MAIN FEATURES

- bulk material consisting of spherical pebbles

- pebble-bed fixed between hot and cold grid

- radial fluid flow

- very high recuperation efficiency up to 98%

- ability to operate at high gas temperatures

- stable outlet temperature of hot blast

- very low exergy loss

Last Project New

Replacement of one hot blast stove (cowper) with a Pebble-Heater.

Feasibility study done by Küttner Ironmaking & Energy GmbH

Cosiderably lower investment costs; most of the periphery equipment may be used.

Patents

- Stromspeicherung über thermische Speicher und Luftturbine

- Storing energy using a thermal storage unit and an air turbine

- Verfahren und Vorrichtung zur Umwandlung von thermischer Energie in mechanische Arbeit

- Method for Converting Thermal Energy into Mechanical Work - decentrilized biomass CHP

- Process for the Operation of a Regenerator and Regenerator

Articles

Customers

|

|

|

|

|

|

|

|